Hazard Assessment

A Hazard Assessment is a record of a pre-job meeting indicating and evaluating the hazards of the work to be completed.

Hazard Assessments are automatically numbered based on the document format specified in the company settings.

Any number of Hazard Assessments may be attached to a Work Ticket.

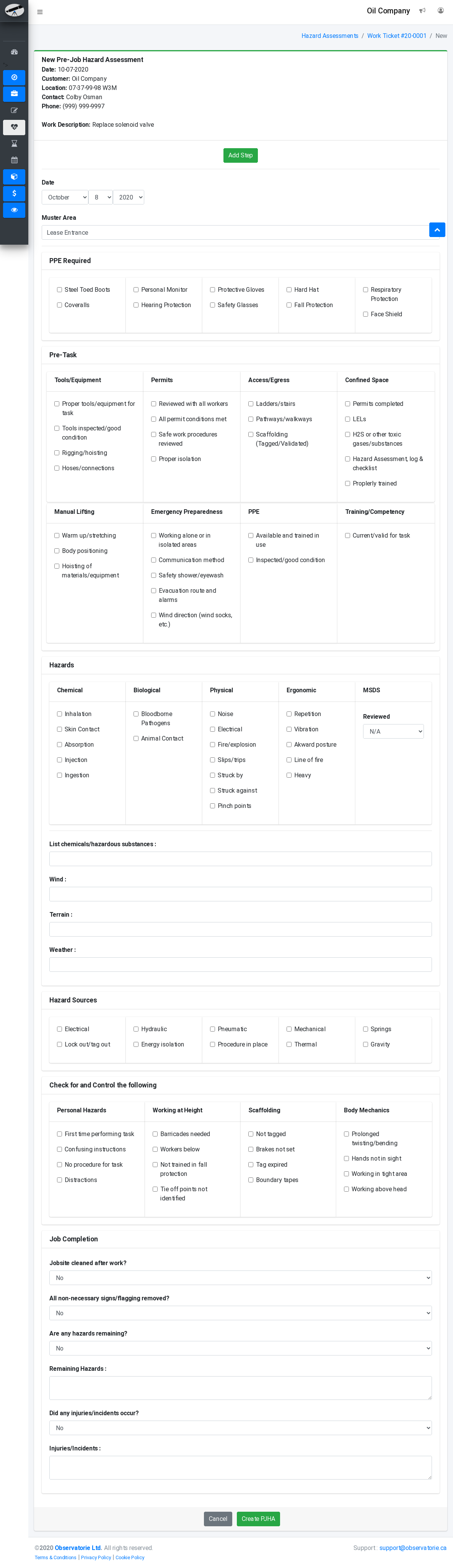

Attributes

- Date - Date of the hazard assessment.

- Muster Area - Location to muster in the case of alarm/event.

Job Steps

Clicking on the 'Add Step' button will display a form for adding a job step to the assessment.

- Task # - Job task number.

- Frequency - Frequency of performing task.

- Consequence - Consequence of performing task.

- Probability - Probability of injury performing task.

- Task - Task to be performed.

- Hazards - Hazards identified.

- Controls - Controls put in place.

PPE Required

- Steel Toed Boots - Check if steel toed footwear is required.

- Coveralls - Check if coveralls are required.

- Personal Monitor - Check if a personal gas monitor is required.

- Hearing Protection - Check if hearing protection is required.

- Protective Gloves - Check if protective gloves are required.

- Safety Glass - Check if safety glasses are required.

- Hard Hat - Check if a hard hat is required.

- Fall Protection - Check if fall protection is required.

- Respiratory Protection - Check if respiratory protection is required.

- Face Shield - Check if a face shield is required.

Pre-Task

- Tools/Equipment

- Proper tools/equipment for task - Check if the proper tools and equipment for the task are available.

- Tools inspected/good condition - Check if the tools have been inspected and are in good condition.

- Rigging/hoisting - Check if the riggin/hoisting equiment has been inspected and is in good condition.

- Hoses/connections - Check if hoses and connections have been inspected and are in good condition.

- Permits

- Reviewed with all workers - Check if the work permits have been reviewed with all workers.

- All permit conditions met - Check if the work permit conditions have been met.

- Safe work procedures reviewed - Check if the safe work procedures have been reviewed.

- Proper Isolation - Check if the necessaey isolation has been carried out.

- Access/Egress

- Ladders/Stairways - Check if ladders and stairways are in good condition.

- Pathways/walkways - Check if pathways and walkways are in good condition.

- Scallfolding (Tagged/Validated) - Check if scaffolding is in good condition, properly tagged and validated.

- Confined Space

- Permits Completed - Check if confined space permits have been completed.

- LELs - Check if LEL level have been measured.

- Hazard Assessment, log & checklist - Check if proper confined space hazard assessments have been completed, logs filled and checklists completed.

- Properly trained - Check if workers are properly trained for confined space.

- Manual Lifting

- Warm up/stretching - Check if warm up and/or stretching has been completed if manual lifing is required.

- Body positioning - Check if body positioning has been considered and risks mitigated if manual lifing is required.

- Hoisting of materials/equipment - Check if hoisting equipment will be used and risks mitigated if lifing is required.

- Emergency Preparedness

- Work alone or in isolated areas - Check if workers will be working alone or in isolated ares.

- Communication method - Check if a communication method/strategy has been planned.

- Safety shower/eyewash - Check if the emergency showers and eyewash stations have been identified.

- Evacuation route and alarms - Check if an evacuation route has been identified and alarms and been reviewed.

- Wind direction (wind socks, etc.) - Check if the wind direction has been noted and the location of wind direction indicators have been identified.

- PPE

- Available and trained in use - Check if specialty PPE equipment is available (such as SCBA, SABA, fire equipment) and workers are trained in their use.

- Inspected/good condition - Check if specialty PPE equipment is good condition.

- Training/Competency

- Current/valid for task - Check if workers are properly trained in the task and any certificates are current and valid.

Hazards

- Chemical

- Inhalation - Check if chemical hazards exist due to the inhalation of substances.

- Skin Contact - Check if chemical hazards exist due to skin contact with substances.

- Absorption - Check if chemical hazards exist due to the absorption of substances.

- Injection - Check if chemical hazards exist due to the injection of substances.

- Ingestion - Check if chemical hazards exist due to the ingestion of substances.

- Biological

- Bloodborne Pathogens - Check if biological hazards exist due to the presence of pathogens.

- Animal Contact - Check if biological hazards exist due to presence of animal life.

- Physical

- Noise - Check if physical hazards exist due to the presence of noise.

- Electrical - Check if physical hazards exist due to the presence of live electrical sources.

- Fire/Explostion - Check if physical hazards exist due to the posibility of fire or explosion.

- Slips/trips - Check if physical hazards exist due to the posibility of slips and trips.

- Struck by - Check if physical hazards exist due to the posibility of being struck by an object.

- Struck against - Check if physical hazards exist due to the posibility of being struck against an object.

- Pinch points - Check if physical hazards exist due to the presence of pinch points.

- Ergonomic

- Reptition - Check if ergonomic hazards exist due to repetitive movements.

- Vibration - Check if ergonomic hazards exist due to vibration.

- Akward Posture - Check if ergonomic hazards exist due to akward posture.

- Line of fire - Check if ergonomic hazards exist due to being in the line of fire.

- Heavy - Check if physical hazards exist due to the presence or use of heavy objects.

- MSDS

- Reviewed - Select whether or not MSDS have been reviewed for hazards of if not applicable.

- List chemicals/hazardous substances - list any chemicals or hazardous substances you may encounter.

- Wind - Make note of wind direction and/or strength.

- Terrain - Make note of terrain conditions.

- Weather - Make note of weather conditions.

Hazard Sources

- Electrical - Check if electrical hazards are present.

- Lock out/tag out - Check if hazards have been mitigated with lock out/tag out procedures.

- Hydraulic - Check if hydraulic hazards are present.

- Energy isolation - Check if hazards have been mitigated with energy isolation.

- Pneumatic - Check if pneumatic hazards are present.

- Procedure in place - Check if hazards have been mitigated with proper work procedures.

- Mechanical - Check if mechanical hazards are present.

- Thermal - Check if thermal hazards are present.

- Springs - Check if springs or other stored energy hazards are present.

- Gravity - Check if gravity hazards are present (such as danger of falling objects from overhead).

Check for and Control the following

- Personal Hazards

- First time performing task - Check if this is the first time performing this task.

- Confusing instructions - Check if this is the task instructions are confusing.

- No procedure for task - Check if no procedure for the task is in place.

- Distractions - Check if distractions are present.

- Working at Height

- Barricades needed - Check if barricades are needed to perform the task.

- Workers below - Check if workers will be present in the area below the work area.

- Not trained in fall protection - Check if workers are not trained in fall protection.

- Tie off points no identified - Check if the tie off points are not identified.

- Scaffolding

- Not tagged - Check if the scaffolding has not been tagged.

- Brakes not set - Check if scaffold brakes are not set.

- Tag expired - Check if the scaffolding tag is expired.

- Boundary tapes - Check if the scaffolding area has not been taped off.

- Body Mechanics

- Prolonged twisting/bending - Check if the task involves prolonged twisting or bending.

- Hands not in sight - Check if the task involves working with the hands out of sight.

- Working in tight areas - Check if the task involves working in tight areas.

- Working above head - Check if the task involves working overhead.

Job Completion

- Jobsite cleaned after work? - Select Yes/No.

- All non-necessary signs/flagging removed? - Select Yes/No.

- Are any hazards remaining? - Select Yes/No.

- Remaining Hazards - List remaining hazards if present.

- Did any injuries/incidents occur? - Select Yes/No.

- Injuries/Incidents - List injuries/incidents if any.

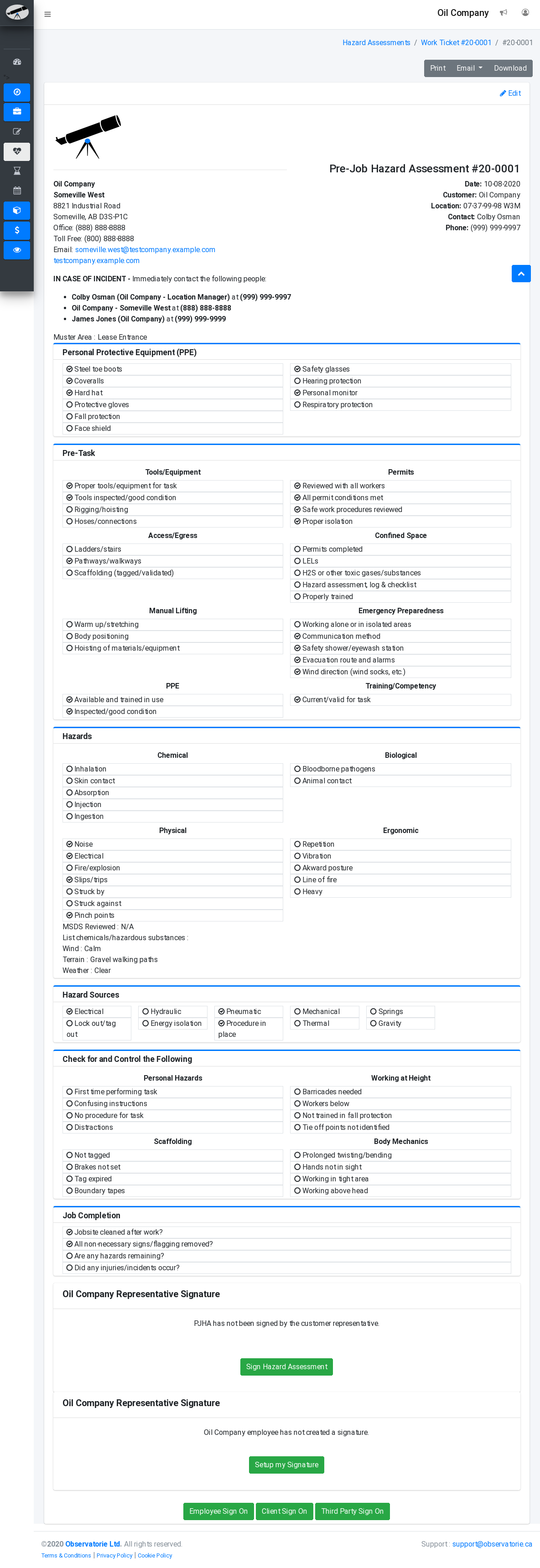

Any number of sign-ons can be added to the assessment by clicking the 'Employee Sign On' button (for employees), 'Client Sign On' button (for clients), or 'Third Party Sign On' button (for any other parties). Doing so will display a sign on form where users can sign on.

Employee Access

| Employee | List View | Detail View | Create New | Edit Existing | Delete | Accessible Assessments |

|---|---|---|---|---|---|---|

| Administrator | Yes | Yes | Yes | Yes | Yes | All assessments belonging to company |

| Head Office Manager | Yes | Yes | Yes | Yes | Yes | All assessments belonging to company |

| Head Office Administrator | Yes | Yes | Yes | Yes | Yes | All assessments belonging to company |

| Branch Office Manager | Yes | Yes | Yes | Yes | Yes | All assessments belonging to branch user is associated with |

| Branch Office Administrator | Yes | Yes | Yes | Yes | Yes | All assessments belonging to branch user is associated with |

| Employee | Yes | Yes | Yes | Yes | Yes | All assessments the user appears on (as creator or signee) |

Client Access

| Client | List View | Detail View | Create New | Edit Existing | Delete | Accessible Assessments |

|---|---|---|---|---|---|---|

| Customer Manager | Yes | Yes | No | No | No | All assessments belonging to customer |

| Customer Operator | Yes | Yes | No | No | No | All assessments belonging to customer |

| Area Manager | Yes | Yes | No | No | No | All assessments belonging to locations of users permitted areas |

| Area Operator | Yes | Yes | No | No | No | All assessments belonging to locations of users permitted areas |

| Location Manager | Yes | Yes | No | No | No | All assessments belonging to locations of users permitted locations |

| Location Operator | Yes | Yes | No | No | No | All assessments belonging to locations of users permitted locations |

Details

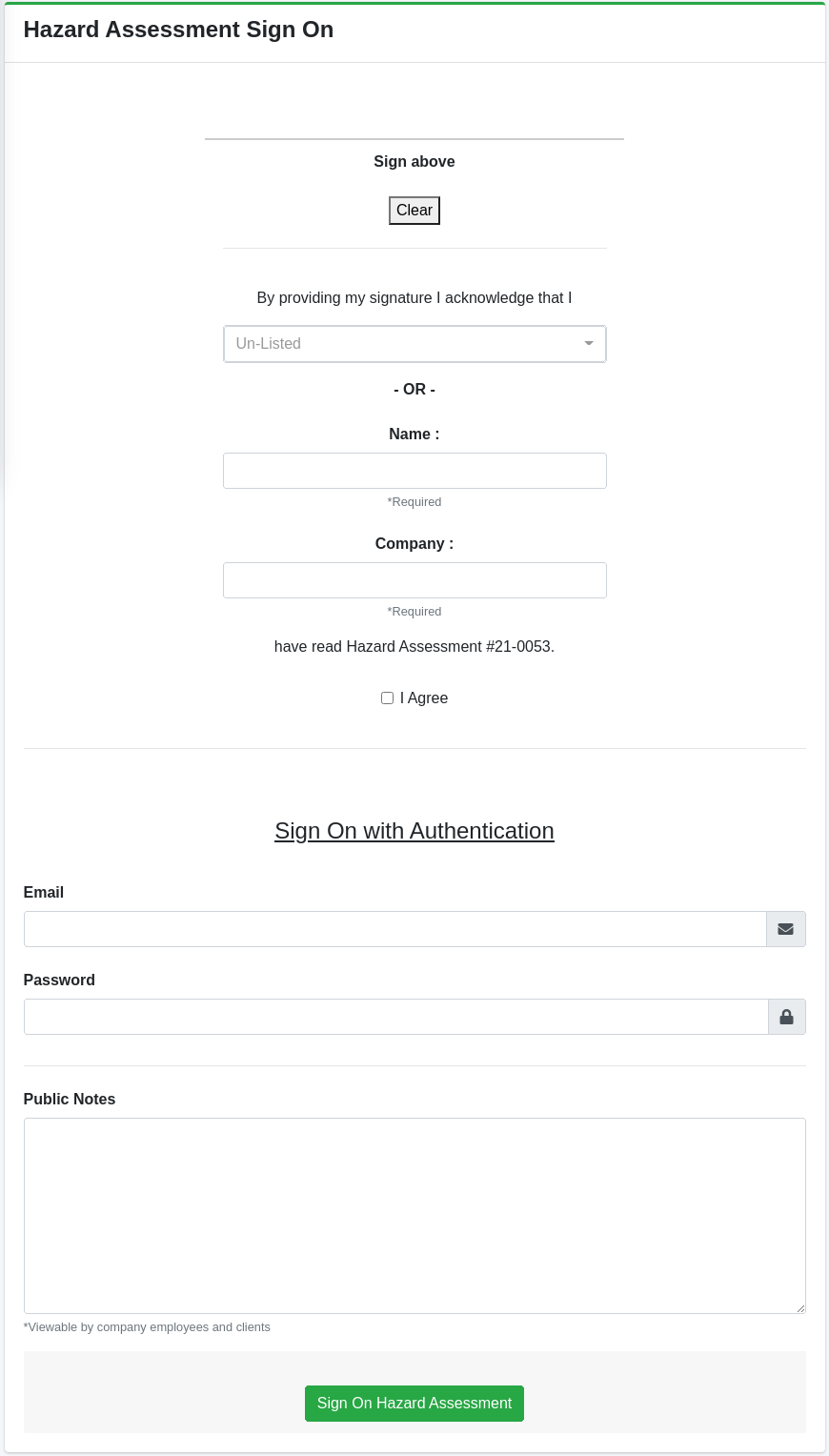

Sign Ons

Employees, Clients and any other workers can sign on to the Hazard Assessment,

Adding assessment sign ons is completed by clicking the appropriate button at the bottom of the assessment view.

The sign on page allows for signature, name capture and notes. Employees can sign on using their email/password.

If the customer allows passwords a Client may sign in to complete the Hazard Assessment Sign On process or provide a name and signature.

A third party can also sign onto a Hazard Assessment by providing a name and signature.